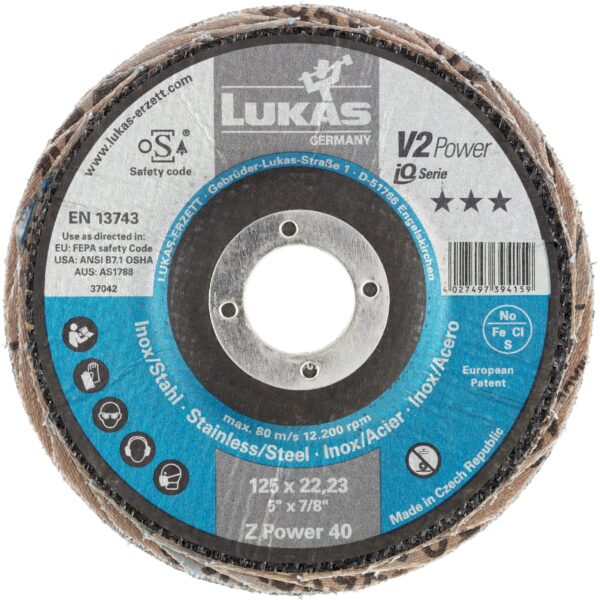

V2 POWER 115 Z Power 40

SKU: PN.03.16.135

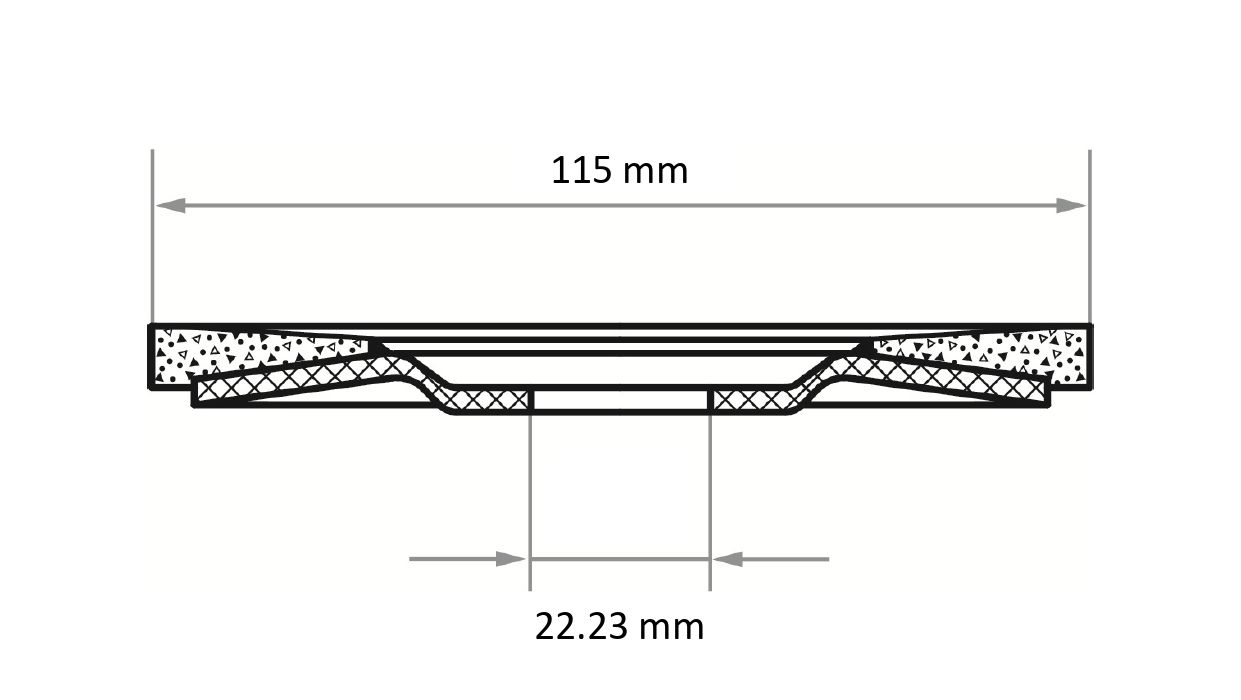

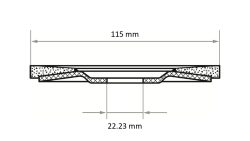

| Outer Diameter (mm) | Ø115 |

|---|---|

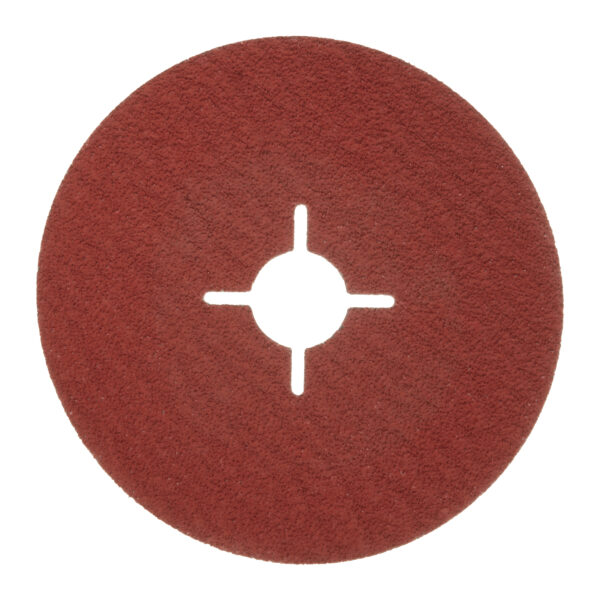

| Product Category | Flap Disc |

| Sand | 40 |

| Hub diameter | 22,23 |

| Product Form | Flap Disc |

| Outside Diameter | 115 |

- V2 Power: optimised for machining stainless steel materials

- Lightweight carrier material for low tool weight

- Maximum tool life thanks to multi-layer abrasive coating

- cost-effective by maximum usage of the entire abrasive coating thanks to specially shaped flaps

- No blue discolouration means less reworking

- Self-sharpening effect: high removal rate especially on stainless steel

- High safety: unbreakable glass-fibre

- Fresh abrasive coating every time: wear exposes the flaps underneath

- More abrasive grains in the outer area for a high grinding speed

- Finished faster thanks to the highest removal rate

- Secure working even at high operating speeds and temperature thanks to special resin bond

- Extremely hard and sharp for an impressively long tool life

- Elastic carrier material: low vibration when working

- Higher performance, work speed and better surface results than with a grinding disc

- Can be used for a long time – no glazing of abrasive grain

- Environmentally friendly production using state-of-the-art resin curing technology

- Also machines hard materials efficiently

- A glass fibre carrier facilitates an exceptional surface result thanks to its flexibility

- Lower vibration – more pleasant working

- Made with top-selling carrier

- Also ideal for machining weld seams

- Inexpensive to purchase

- Higher safety thanks to an optimised bond of the flaps

- Excellent use of abrasive grains thanks to a flat arrangement for a long tool life

- Quieter: 50% less noise than common grinding discs

- Innovative tool: LUKAS exclusive

- Can be used with any commercially available angle grinder thanks to 22.23 mm bore

- Tested quality: high level of safety through regular testing

- The flexible, lightweight, stable and elastic glass fabric carrier of the tool allows for exceptional surface results. The high resistance to shredding and minimal vibration during operation, not to mention its easy handling, perfectly round off this tool.

- Thanks to the multi-layer coating, this tool is always as sharp as at the first time of use. When the top flaps wear down, the fresh abrasive coating of the flaps underneath is exposed. In this way, they achieve a long service life and consistent working quality.

- The flat position of the optimally bonded flaps not only makes for safer working, but also cuts down the tool wear. The abrasive grain adheres particularly firmly to its backing and is optimally used. A particularly large concentration of abrasive grains on the outer perimeter results in an exceptionally high removal rate per minute. Outstanding removal rates are guaranteed.

- The abrasive surface layer of the abrasive cloth makes it easier for you to work with it. Thanks to the cool grinding, blue discolouration and glazing are a thing of the past.

- Thanks to the self-sharpening effect of the zirconia alumina, combined with the extreme hardness and sharpness of the abrasive grain, this tool achieves high removal rates and a long service life, especially with hard and tough materials such as stainless steel.

- The flat position of the optimally bonded flaps not only makes for safer working, but also cuts down the tool wear. The abrasive grain adheres particularly firmly to its backing and is optimally used. A particularly large concentration of abrasive grains on the outer perimeter results in an exceptionally high removal rate per minute. Outstanding removal rates are guaranteed.