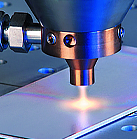

Tools for quick cleaning and cutting

We have developed the VDC diamond cutting disc specifically for cutting grey cast iron (GG, GGG). It also performs fantastically when working on GFRP and mineralisation. With its diamond cutting edges, it cuts aggressively while having an extremely long tool life. It generates hardly any heat and works free of dust and odours. This disc is also perfect for quickly cutting cast pipes.

Only the very best tools are good enough for your cast workpieces. These are the most popular tools from the LUKAS range for machining cast parts:

- VDC diamond cutting disc

- Cast burrs

- HK/MK mounted points

- T41/ T42 cutting disc

The distinguishing feature of the Cast burrs are their faceted toothing. This enables the burrs to achieve high removal rates on cast materials and smooth tool guidance at the same time. The high-quality tungsten carbide on the milling head guarantees a long service life. This makes it ideal for cleaning, deburring and chamfering cast workpieces. The Cast burr is available in different head shapes and with head diameters between 6 and 12 mm.

We have designed our HK and MK series mounted points primarily for use with cast materials. Their grain mixtures and the resilient bonding agents are especially suitable for powerful work on cast steels. This includes rapidly grinding off sprues and burrs. A remarkable feature of the LUKAS mounted points is that they run smoothly, which makes working process even, gentle and effortless. The mounted points are available with head diameters from 10 or 16 mm to 50 mm.

The T41/T42 cutting disc is a universal tool for expertly machining concrete, stone and cast material. This makes it ideal for craftsmen who cut different materials on the construction site. Be it brick, concrete or cast pipes, nothing can stop this cutting disc. The high proportion of silicon carbide in the cutting materials ensures a strong cutting performance. The T41/42 is often used in foundries for cutting off risers and sprues as well as for removing defects.