Tools for power plants and energy technology

LUKAS has developed special grinding and milling tools for the power generation and environmental industries. The grinding of large blades made of GFRP/CFRP laminates in particular is one of the most challenging tasks where wind turbines are concerned. That is why most manufacturers of such systems work with premium-quality LUKAS tools. Our burrs are frequently used in the construction of gear units for the wind energy sector.

Here are some of our most popular tools in the environment and energy industry:

- V2 Power “Alu” lamellar flap disc

- Burrs

- SHF semi-flexible grinding disc

- VDC diamond cutting disc

The V2 Power flap disc provides a high machining capacity for large areas such as wind turbine blades. The patented shape and arrangement of the flaps and the increasing density of the abrasive grains in the outer area contribute to this. The benefit of the six abrasive layers is that as soon as one layer wears down, the next one intervenes immediately. In this way, the V2 Power not only achieves a high removal rate but also a long service life. The “Alu” version features silicon carbide abrasive grain. This abrasive material works perfectly on composite fibre materials such as CFRP and GFRP.

Grinding becomes a refinement

The P6 marbling point creates grinding effects that look like peacock feathers or clouds. It can be used on stainless steels, aluminium and non-ferrous metals. This treatment gives kettles and vessels a decorative surface. The grinding wheel is available with head diameters between 20 and 60 mm. The tool does not clog up while working and can be used until it has been ground down completely. Finally, further polishing to achieve a mirror finish is recommended.

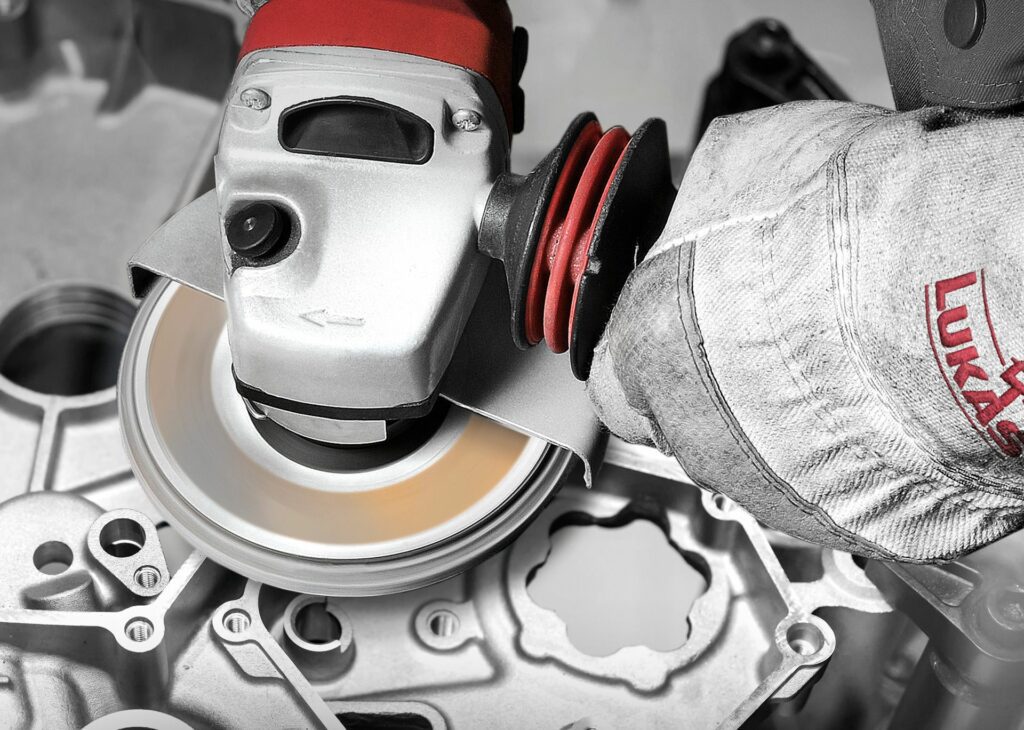

Wind turbine blades require thorough rough machining prior to grounding. This is where the SHF semi-flexible grinding disc come into it’s own. It has a dense silicon carbide coating on its fibre plate, which allows this grinding disc to forcibly remove CFRP, GFRP and other fibre-reinforced materials. On metal, it is used for coarse work such as derusting and paint stripping. The grinding disc is used on angle grinders together with a backing pad.